Elliott Multi-Stage Centrifugal Compressors are engineered to deliver superior performance and reliability across a wide range of industrial applications. Backed by over a century of innovation, Elliott’s compressors incorporate cutting-edge aerodynamic, rotordynamic, and metallurgical advancements to meet the most stringent operational and environmental standards. From their robust casing designs to their high-efficiency impellers, Elliott compressors are built for demanding environments, ensuring optimal efficiency, increased stability, and reduced maintenance costs for your critical processes.

Key Features:

- Superior Aerodynamic Efficiency:

Utilizes state-of-the-art interactive design tools, CFD analyses, and dynamic simulations to optimize aerodynamic performance and achieve high operational efficiencies.

- Improved Rotor Stability:

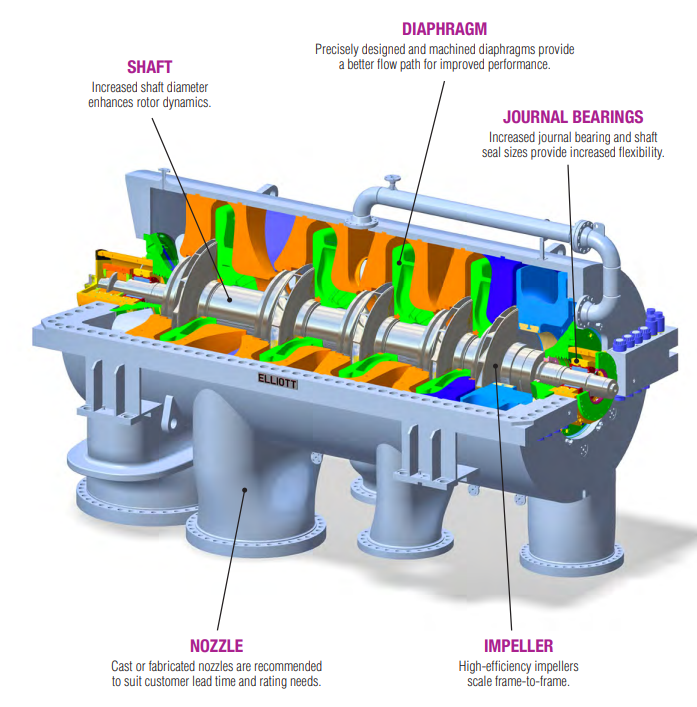

Developed proprietary analytical tools through extensive research in rotor-dynamic stability, aerodynamic cross-coupling stiffness, and rotor-bearing systems, leading to product enhancements like increased shaft diameter and larger journal bearing sizes for higher torque transmission and speed.

- Robust Casing Design:

Features innovative casing designs that simplify manufacturing and field assembly, with integral horizontal flanges on small and medium frames, machined flats with SAE flanges, and high-strength through-bolts for superior clamping forces. Vertically split MB-line compressors offer a complete inner casing assembly for easier installation and reduced turnaround times.

- Advanced Aerodynamic Components:

Offers superior three-dimensional impeller designs and stationary diaphragms, optimized for various pressure and flow applications using the latest design and analysis technologies. Impellers are manufactured with five-axis milling for quality, and diaphragms are precisely machined for dimensional accuracy and improved surface finish.